Can I Iron Deli Paper Sheets?

Deli paper also known as sandwich paper, is a versatile material often used in food service establishments for wrapping sandwiches and other handheld items. But beyond its use in the kitchen, deli paper has earned popularity in the arts and crafts community as well. One question often arises in this context: “Can I iron deli paper?”

In this blog post, we will delve into the fascinating world of deli paper and ironing. We will examine the composition of the deli paper, discuss the potential risks and benefits of applying heat to it and provide practical guidance on whether or not ironing this delicate material is a viable option. So stay tuned!

Ironing Deli Paper Sheets

To answer the question is “YES”, you can iron deli paper but with caution. Deli paper is not designed to withstand high temperatures. Deli paper is typically composed of wax-coated parchment or waxed Kraft paper. This coating gives the paper its signature glossy surface while also providing a layer of protection against moisture.

However, when exposed to high temperatures of iron, this protective coating can melt and leave a sticky residue on the fabric. It is for this reason that we recommend caution when attempting to iron deli paper.

If you do decide to use an iron, make sure you are using low heat and move the iron quickly over the paper.

Additionally, you should use a pressing cloth (such as an old towel or T-shirt) to protect the paper from direct contact with the iron. The heat applied by an iron can help to further seal and preserve the wax coating of the deli paper, making it an even more sturdy and durable material.

Pros and cons of ironing the deli paper

Pros

- Smoothness: Ironing deli paper can smooth out any creases or folds, resulting in a clean, neat appearance. This is particularly helpful for crafting purposes, where a smooth surface can improve the final product’s appearance.

- Sealing: The heat from the iron can further seal the wax coating on the deli paper, enhancing its moisture resistance. This could be beneficial when using deli paper for food packaging.

- Versatility: Ironed deli paper can be used in various crafts, from scrapbooking to mixed media art, adding a smooth, wax-like texture to your creations.

- Removing Moisture: If the deli paper has come into contact with moisture and is slightly damp, ironing it on a low heat setting can help remove the moisture and restore its dryness.

Cons

- Melting Risk: As mentioned previously, the wax coating on deli paper can melt under high heat, potentially damaging the paper or leaving a sticky residue on your iron or ironing board.

- Fire Hazard: Applying heat to any paper product always carries a potential fire risk. It’s crucial to use low heat and never leave the iron unattended.

- Time-Consuming: Depending on the amount of deli paper you need to iron, the process can be quite time-consuming. It requires careful attention to ensure you don’t damage the paper, making it potentially impractical for large quantities.

- Staining: If the deli paper has any ink or printing on it, ironing it could cause the ink to spread or transfer onto the iron’s surface. This could potentially stain both the iron and the paper itself.

It is important to be aware of the pros and cons before attempting to do so. If done correctly, however, ironing can help you achieve a smooth finish for your projects or food packaging needs.

Factors to consider before ironing deli paper sheets

Before you begin ironing deli paper, there are a few critical factors to bear in mind:

- Material Composition: Deli paper is typically made from lightweight and porous materials. Before ironing, check the composition of the paper to ensure that it can withstand heat and pressure without melting, sticking or releasing harmful fumes.

- Heat Resistance: Consider the heat resistance of the deli paper. Deli paper is not designed to withstand high temperatures like ironing boards or clothes, so there’s a risk of scorching or burning the paper.

- Moisture Content: Moisture can affect the paper’s texture and integrity. Ironing damp or moist deli paper might cause it to wrinkle, tear or become translucent.

- Iron Temperature Setting: Make sure the iron is set to low heat. A high temperature could cause the wax coating of the deli paper to melt and leave a sticky residue on fabrics or other surfaces.

- Ironing Surface: When ironing deli paper, use a flat, heat-resistant surface. This will help to ensure even and consistent pressure when ironing the paper.

- Safety: Always prioritize safety. If at any point you notice the paper discoloring, emitting an unusual odor or showing signs of damage, stop immediately to prevent any potential hazards.

Following these steps should help you safely and effectively iron deli paper for your projects or food preparation needs.

Also Read: Is Deli Paper Acid Free?

How to iron the deli paper?

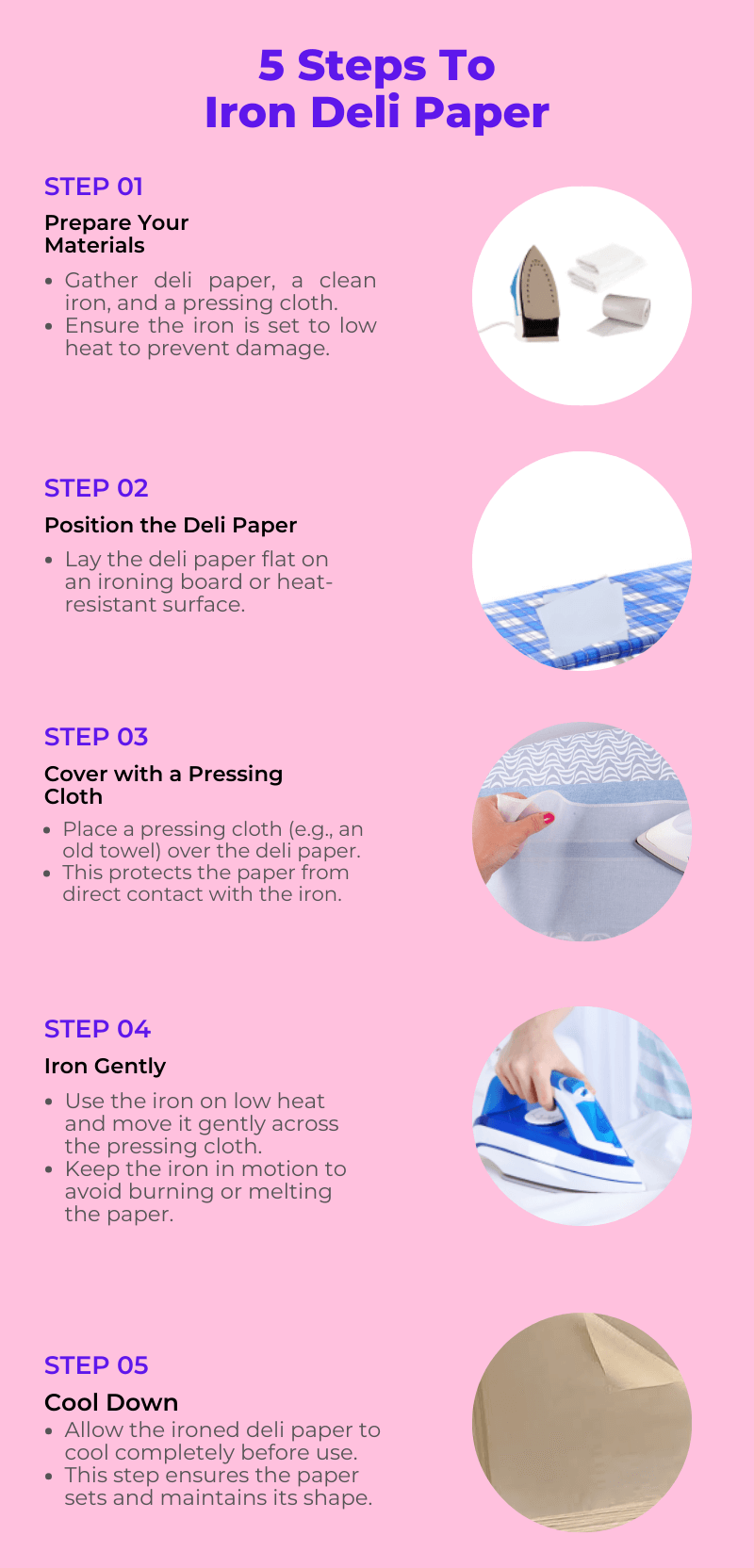

Here is a simple step by step guide on how to properly iron deli paper:

- Prepare your materials. Gather your deli paper, a clean iron and your pressing cloth. Make sure your iron is set to a low-heat setting to avoid burning or melting the paper.

- Position the deli paper. Lay the deli paper flat on an ironing board or a flat, heat-resistant surface.

- Cover with a pressing cloth. Place your pressing cloth over the deli paper. This will protect the paper from direct contact with the iron.

- Iron gently. With the iron set to low heat, gently move it across the pressing cloth. Keep the iron moving to avoid potentially burning or melting the deli paper.

- Inspect the paper. After ironing, carefully lift the pressing cloth and check the deli paper. If it’s not smooth enough, repeat the process until you achieve the desired result.

- Cool down. Allow the paper to cool fully before using it for any project.

Using these steps, you should be able to safely iron your deli paper without worrying about damaging it. Remember, always keep safety in mind when working with heat-sensitive materials.

Other alternative methods

While ironing can be an effective method for smoothing and enhancing deli paper, there are also several other techniques you might want to consider:

- Book Pressing: For smaller pieces of deli paper, you can use book pressing. Simply place the paper between the pages of a heavy book and leave it for a few hours or overnight. The weight of the book will help to flatten any creases or wrinkles.

- Weight Pressing: If you’re working with larger pieces of paper, place them under a flat, heavy object like a board or a box. Again, leave it for a couple of hours or overnight.

- Hair Dryer: A hairdryer can also be used to smooth deli paper. Place the paper on a flat surface, hold the hair dryer about 6 inches away and move it around to evenly distribute the heat. Be sure to use a low heat setting to avoid damaging the paper.

- Spray Starch: Spray starch, commonly used in laundry, can stiffen paper and help to smooth out any wrinkles. Lightly mist the deli paper with the spray, then flatten it out by hand or under a heavy object.

- Adhesive Spray: Adhesive sprays can also be used to enhance deli paper. Simply spray one side of the paper, then smooth it onto a surface. This can be especially useful for craft projects.

Remember, each method has its own set of benefits and possible drawbacks, so it’s important to choose the right one based on your specific needs and the type of deli paper you are using.

Also Read: Deli Paper vs Parchment Paper?

Wrap Up

It is indeed possible to iron deli paper. This versatile and lightweight paper, often used for food wrapping and crafting, can be effectively ironed on a low to medium heat setting.

However, it’s crucial to exercise caution during the process to prevent the paper from scorching or melting.

By using a gentle touch, low heat and a protective cloth, you can successfully iron deli paper to smooth out wrinkles and achieve desired results without damaging the paper. Always conduct a small test in an inconspicuous area before proceeding to iron larger sections.